扬程:-1500m

流量:-2500m³/h

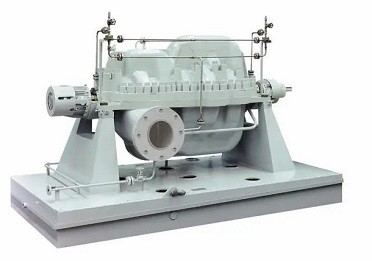

1、轴向剖分、水平中开结构,维修时可不必拆卸进出口管路,而且联轴器端为锥轴设计,方便设备检修维护

With axial direction and longitudinal intermediate structure, it is not necessary to dismantle outlet pipe for repair. Besides, with cone axis design of coupler end, it is convenient in equipment overhaul and maintenance.

2、按API682标准密封腔设计,采用集装式机械密封,便于安装和维修,轴向压缩量不受任何连接件轴向尺寸影响,无需调整。

Packaging-type mechanical seal is adopted according to seal design of API682 standard. It is convenient in installation and maintenance. The axial compression is free of influences of axial dimensions of any connecting pieces. It is not necessary to make adjustment.

3、轴承架为带散热片的铸钢件,采用新型非金属同步甩油环,润滑更加充分,并减少润滑油污染;配套专用轴承压盖,可满足油雾和油浴润滑的双重需要。

The bearing support is steel coasting with cooling fin. With new-type non-metal synchronic oil slinger, it is further sufficiently lubricated and pollution of lubricating oil is reduced. With special bearing gland cover, dual requirements of oil mist and bath lubrication can be satisfied.

4、优化轴承结构,选用球/球、滑动/球及滑动/止推轴承等形式,给转子部件提供最佳支持。

By optimizing axial structure and selecting ball-ball and sliding-ball and sliding-thrust bearing forms, the optimal support can be provided for parts of rotor and the cost for bearing and support system can be maximally reduced.

5、管口按API标准三倍载荷设计,采用API标准底座,确保运转安全、稳定、可靠。

Pipe orifice is designed according to API standard twofold load. API standard chassis is adopted to ensure safe, stable and reliable operation.

6、依照水力性能优化设计的锻造增强型刚性阶梯轴(将来根据需要可使用空段),满足功率传递要求,提高转子可靠性,符合API610的典型设计方案。

With enhancement rigid stepped shaft (dead band can be used according to the requirement) optimized and designed according to hydraulic performance, power transmission requirement can be satisfied and rotor’s reliability can be enhanced and typical design scheme of API610 can be satisfied.

7、叶轮背对背布置,整体平衡管路和节流衬套,最优结构平衡轴向力。

With back-to-back arrangement of impeller, pipeline and nockbush can be overall balanced

to optimize structural balance axial force.

8、双蜗壳结构形式,精密铸造叶轮,可保证最小水力径向力。

With double-volute structural form, precision cast impeller can guarantee minimum hydraulic

radial force.

9、BB3 - 标准型,为单吸叶轮,背靠背布置;

BB3-standard, single-suction impeller, back-to-back arrangement;

BB3D -首级叶轮双吸结构,提高抗汽蚀能力,

降低吸入比转速;

BB3D-first-stage impeller with two-suction structure enhances

anticavitation capacity and reduces suction specific speed;

性能参数Performance parameters:

流量Flow quantity:~2500m3/h

扬程Lift :~1500m

工作压力Working pressure:25MPa

工作温度Working temperature:-20℃~+200℃

30年水泵研发生产经验,技术力量雄厚,无忧售后,中石化一级甲级供应商,产品值得信赖。